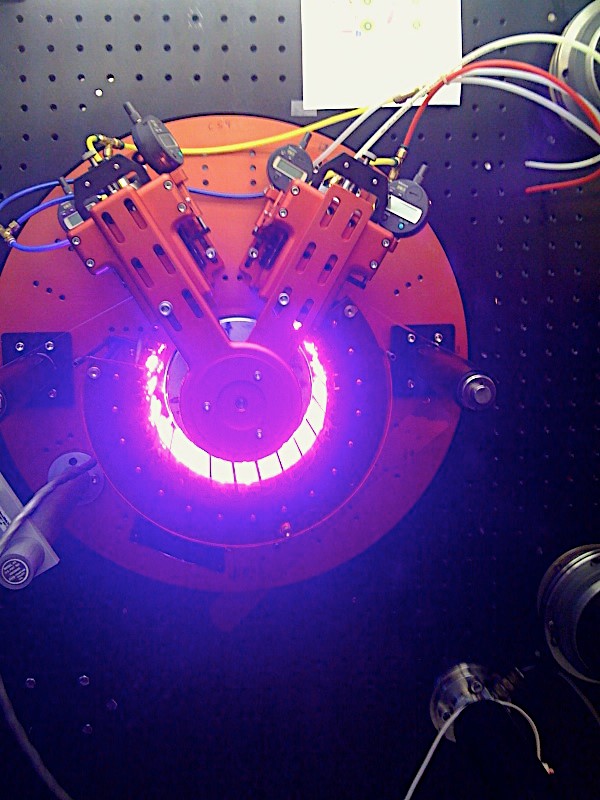

In addition to batch processing, our patented nanopatterning processes have also been designed for continuous roll-to-roll (R2R) manufacturing. R2R manufacturing enables precise micro- and nanoscale 3D polymer structures and metal patterns to be made in higher volumes, over larger areas and at lower cost.

Our batch and R2R processing works with a wide range of films—either transparent or opaque—including polymers (PET, PEN, polycarbonate, PMMA, Zeonor and Topas cyclic olefins, polyurethane, polyimides and others), metal foils (Al, Cu, Ni, stainless steel, etc.), and even paper. Depending on the material, substrate thicknesses can range from less than 5 microns (1/4 mil) to 750 µm (30 mil).

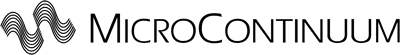

When beginning the development of a custom R2R process, it is often more efficient to initially demonstrate early-stage concepts using batch processing techniques designed to directly scale to R2R production. Our unique batch approach simulates the key R2R processes while allowing more flexible experimentation, rapid evaluation of process parameters, and significant reduction in material waste during early stage development. Once key parameters have been determined, the process can efficiently be transferred to one of our three R2R pilot lines for further refinement and larger volume production.

Using either our Advanced Surface Nanoforming™ or UV processes— batch or R2R—we can create customized solutions that meet a broad range of material, structure, and cost requirements.

Benefits of Roll-to-Roll Nanopatterning

Applications of Roll-to-Roll Nanopatterning

Transparent Conductors

Flexible Electronics

Light Control Films

Wearable Sensors

Organic LED Substrates

Enhanced Solar Cells

Work with us to research, develop and launch your project!