Company leverages its nanofabrication technology to produce robust SERS substrates for R&D and commercial use

MicroContinuum, a nanomanufacturer of technologies to make micro- and nanoscale structures, textures, and embossed patterns on flexible and rigid substrates, announced it has launched a series of Surface Enhanced Raman Scattering (SERS) substrates for R&D and commercial use.

Raman spectroscopy results from the the interaction of light with the chemical bonds of the target materials to produce a “chemical fingerprint.” This fingerprint, while highly specific, has very low intensity. To amplify these weak Raman signals, SERS uses patterned nanometallic substrates that create surface plasmon resonance that significantly enhances the Raman signal, typically by as much as a million-fold. The result is a surface that provides both high intensity and high specificity for SERS detection of trace amounts of chemical and biological materials.

SERS technology is currently used in several areas, including pharmaceutical development; bioassays, such as for detecting low-concentration biomarkers; chemical threat screening, such as chemical warfare agents, explosives, and energetic materials; narcotics detection; environmental contaminant detection; and food quality analysis. However, use of high-performance SERS substrates has been limited because it is analyte dependent and has high manufacturing costs, poor repeatability, and background contamination. MicroContinuum’s new process overcomes all these limitations.

MicroContinuum has served the research community for over 25 years with its patented nanopatterning technology that creates customized nanostructures for cost-effective high-volume use. Recognizing the need for improved SERS substrates, the company utilized its existing proprietary nanofabrication technology to develop a library of analyte-specific SERS substrates for companies to leverage for medium to high-volume applications.

“Until now custom-patterned SERS substrates with high uniformity and low contamination levels have not been available, especially at a low cost,” said MicroContinuum’s CEO Dennis Slafer, Ph.D. “We’re working with customers to provide a SERS test matrix of various structures and customized patterns for specific applications that will allow them to optimize SERS detection for their target chemicals. Additionally, the low cost will expand their test capabilities.”

The SERS series is available with several configuration options:

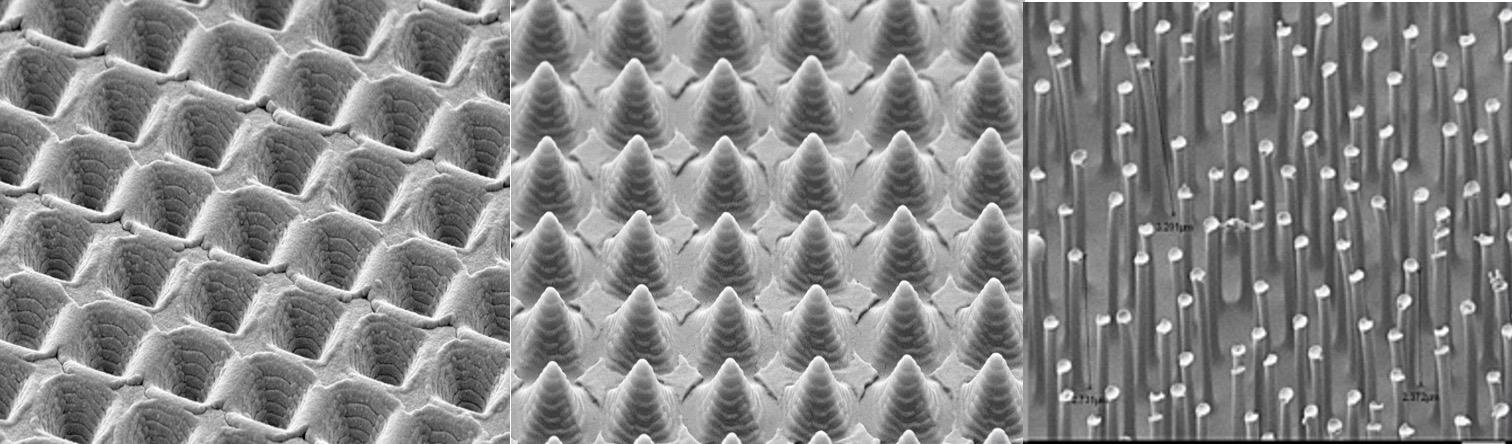

- Surfaces consist of periodic arrays of metalized 3D relief structures.

- Can be formed in both positive (raised) and negative (sub-surface) geometries.

- Can be coated with a range of metals, including Au, Ag, Cu, Al, and metal oxides.

- Can be produced in various polymer films, including polycarbonate, cyclic olefin (ZeonorTM and TopasTM), acrylic, cellulose esters (CAB, CAP), amorphous PET, and other substrates.

- Can be used stand-alone or mounted on a support, such as glass, quartz, Si, or metals, per customer requirements.

Interested companies and individuals should contact MicroContinuum.