Transparent wire grids made with wire having diameters of several microns or smaller can be produced on flexible or rigid substrates, including polymers, glass and even paper. The grids can help decouple the electrical and optical properties of the substrate, producing thin films with high electrical conductivity and high optical transmission. The grids can be produced with different metals for the wires, various diameters down to nanometers, various spacing between the wires, and many types of grid patterns.

Applications

Wire grids can be designed and fabricated:

- to improve the electrical and optical properties of transparent conductors.

- to provide a transparent EMI (electromagnetic interference) shield with certain wavelengths reflected or absorbed.

- to reflect microwave radiation to improve the transparency of microwave oven windows while also reducing microwave radiation outside the oven.

- to increase light extraction from LEDs to improve their efficiency.

- to improve the light absorption of certain optical devices including solar cells.

- to produce thin flexible films that can wavelength shift electromatic radiation for cloaking and other types of applications.

Use case

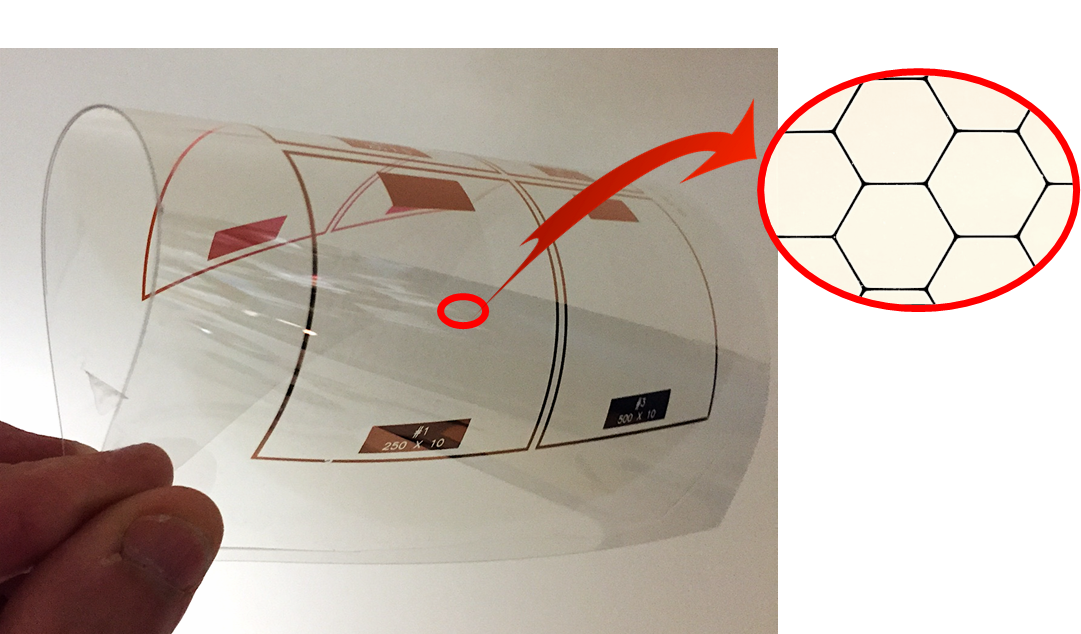

Figure 1 – An example of a custom copper grid made by MicroContinuum that met customer specs for an ‘invisible conductive grid’ with having 900nm wide lines, >98% open area, 30Ω/square sheet resistance that must exceed 30,000 small angle bends (ours did not fail even after 40,000 bends at the end of the test)

For additional information, please contact:

781.635.7032